Customer test report oil service unit FAPC16 - machining center

Customer:

A company from the machining industry with 25 years of experience, based near Munich. Then as now, they see themselves as suppliers of ready-to-install components. Using the latest technology, we realize approx. 80 employees your ideas. This customer supplies a wide variety of components/modules of the highest quality in the field of light metal casting.

Machine/system:

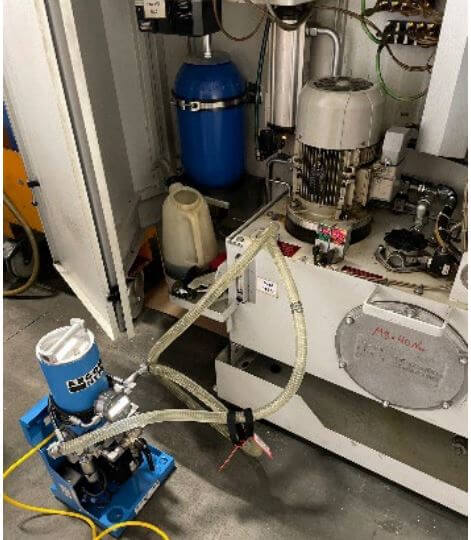

Hydraulic unit on a CNC machining center Tank volume

approx. 60 liters, HLP 46

Challenge:

In order to always meet customer delivery deadlines on time, it is very

important that the machines and systems are always reliable.

and function safely. Only in this way can existing

Optimum utilization of production capacities. For this reason, great importance is attached to preventive maintenance and servicing.

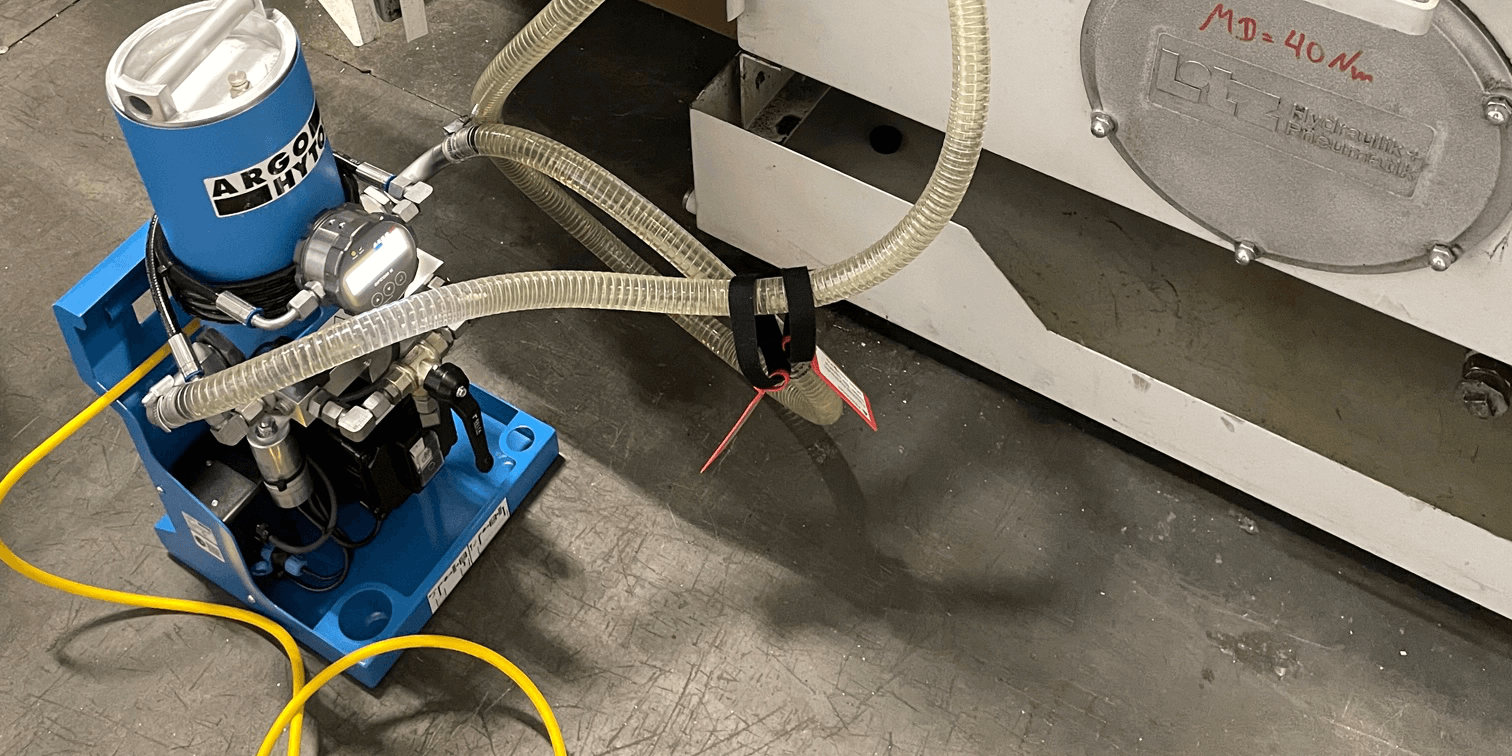

As part of a customer visit, we presented the oil service unit

FAPC016 and spontaneously decided to give it a try.

Filter system used:

Type: FAPC016 with particle counter

Filter capacity: 16 liters/min.

Filter fineness: 3µm

Result:

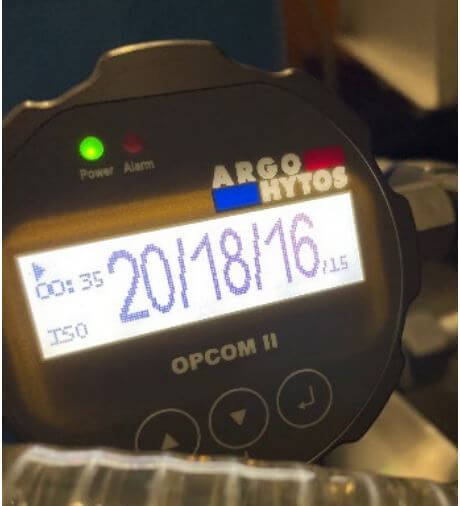

Interestingly and surprisingly, the cleanliness class required by the machine manufacturer in accordance with ISO 4406 – 17/15/12 was not met.

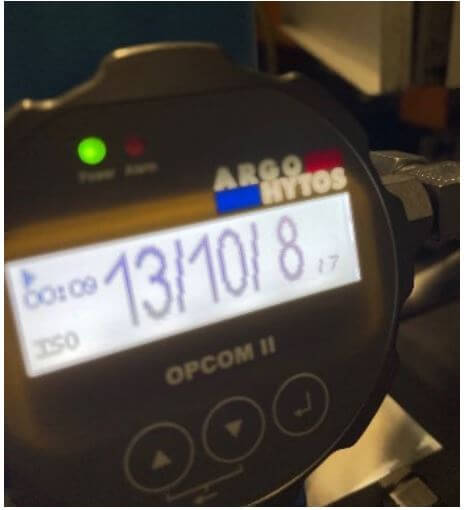

At the start of filtration, we had a purity class of 20/18/16 (Fig. 2). After just 60 minutes, we scored the

purity class 13/10/8 (Fig. 3), which is very good for this application.

Our customer’s maintenance manager is very satisfied with this result and is considering purchasing the filter system.

Side note: Due to the large dirt holding capacity of approx. 280g, the filter element used can also be used to filter other hydraulic systems. As a result, the ongoing operating costs of the off-line filter system are also low.

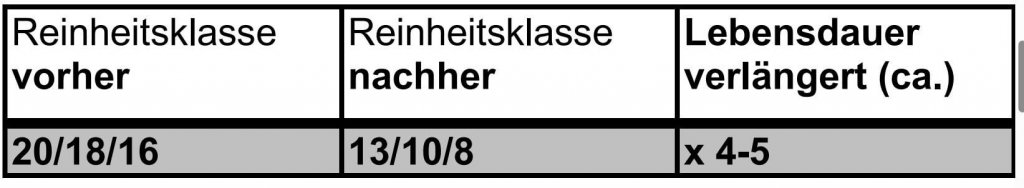

The service life of hydraulic and lubrication system components changes significantly depending on the cleanliness class: