For further helpful information, please visit us at fluidpflege.de

The role of oil condition sensors is becoming increasingly important in hydraulics. Around 70-80% of hydraulic failures are caused by contaminated fluids. Dirt particles are often introduced from outside and continuously impair the cleanliness of the oil. Contamination of the oil has a negative effect on the service life of hydraulic components. With proportional control valves, a small particle can cause the valve to malfunction. A pump or valve failure usually leads to a machine standstill with devastating consequences and costs. Clean and dry oil ensures that the hydraulic system functions perfectly and reliably. Oil condition sensors can be used to continuously monitor the contamination of hydraulic oil. This allows the hydraulic system to be accessed as soon as the oil quality deteriorates.

For further helpful information, please visit us at fluidpflege.de

Optical particle counters work with a so-called “light blocking method”. The medium under investigation is illuminated using LEDs or laser light. The particles to be counted are individually measured optically and the number and size of the particles are evaluated electrically using numerical methods. With particle counters, the hydraulic fluid is analyzed continuously, automatically and almost in real time. This ensures complete documentation of the conditions according to cleanliness class so that changes can be responded to in good time.

It is important to monitor the condition of hydraulic fluids as over 80% of failures are due to particulate contamination. The hydraulic oil must be checked for its actual degree of contamination, as the filter performance requirements vary depending on the ambient conditions. Removing the oil from the system and examining it under a microscope is both imprecise and very time-consuming.

Particle counters permanently monitor the hydraulic oil, so that quick action can be taken if the oil purity deteriorates and, for example, the hydraulic filters can be changed.

Oil condition sensors or oil quality sensors provide real-time monitoring of the actual contamination and water content in the oil. The oil condition sensor is a cost-effective solution for permanently monitoring the oil condition in hydraulic systems, combustion engines or lubricating oil systems. The need for effective monitoring of critical systems and machines is becoming increasingly important:

The measuring method of most of these sensors is based on measuring the dielectric constants. Our OQS also measures the so-called “effective resistance”, which means that the sensitivity of the sensor is approx. 30 times greater than that of conventional oil condition sensors.

ARGO-HYTOS hydraulic filter elements meet the highest standards of performance and quality. Only original parts guarantee that a reliable level of performance can be maintained. We are a long-standing partner of ARGO-HYTOS, where you will find a large number of filter elements, also in exchange for other manufacturers.

The LubCos H2O+ II is a stationary screw-in sensor for the continuous determination of the oil condition. Furthermore, both the oil moisture and the temperature in hydraulic and lubricating oils are determined.

The oil quality sensor gives you control over real-time monitoring of oil deterioration, oil condition and water ingress. Expensive oil changes are therefore based on the oil condition and not on a historical schedule. The OQS oil condition sensor detects all types of wear and contamination:

Further advantages of the OQS oil condition sensor:

The ICM 2.0 is an inline particle counter with LED measuring technology. This particle counter is used to automatically measure the solid contamination, temperature and relative humidity content of hydraulic fluids. The ICM is intended for permanent use and is permanently installed in a hydraulic circuit.

The ICM can be operated both manually on the device and via a remote control (using a PC, laptop or tablet). The device can be controlled externally via a second signal connection. It remains integrated into any system control. The ICM 2.0 works with a unique LED measuring technology, and the advanced measuring cell achieves an even finer resolution in particle counting.

Advantages:

Mobile oil diagnosis device from Argo Hytos

The Portable Oil Lab is a mobile oil analysis device for service and maintenance staff for on-site analysis. No more waiting times. Safe and fast measurement without a laboratory. Discover the advantages!

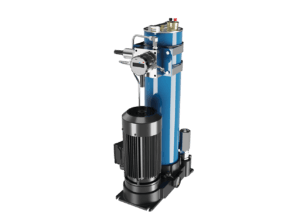

Off-line filter system for stationary or mobile applications from

Argo Hytos. Off-line filter units are suitable for use in the off-line flow of hydraulic and lubricating oil systems.