Customer test report oil service unit FAPC016 - Machine for the production of wire products

Customer:

Our customer is one of the leading manufacturers of wire solutions, characterized by the introduction of innovative production techniques and the use of computer-aided solutions. Thanks to these cutting-edge technologies, the Group can ensure that its products are of a consistently high quality, regardless of where they are produced. Although the Group was primarily active in the wire sector in its early days, it has significantly expanded its product range over the decades and developed additional technologies. As a result, they are now leaders not only in wire processing, but also in various other complementary areas of technology.

Machine/system:

Hydraulic unit under basket line, tank volume approx. 60 liters, HLP 46

Challenge:

To maximize machine availability and ensure trouble-free operation, our customer relies on proactive maintenance. This includes regular laboratory analyses of oil samples from the hydraulic units. Significant oil wear was detected in some samples, which required the hydraulic oil to be changed. For systems in which the contamination of the oil exceeds the permissible degree of purity, off-line filtration would be the appropriate solution. This method helps to continuously ensure the purity of the oil without the need for a complete oil change.

During a product demonstration, we presented the FAPC016, a device with a particle counter, and installed it on one of the systems with contaminated oil.

Filter system used:

Type: FAPC016 with particle counter

Filter capacity: 16 liters/min.

Filter fineness: 3µm

Result:

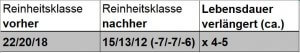

After connecting the oil service unit, it quickly became apparent that the hydraulic oil was heavily contaminated. A purity class of 22/20/18 determined in accordance with ISO 4406, which was also confirmed by the laboratory, clearly exceeded the generally recommended purity grade. After the FAPC016 had been in operation for around 3-5 hours, we achieved a purity class of 15/13/12 – an excellent result.

Additional information: Thanks to the filter element’s considerable dirt holding capacity of around 280 g, it can be used for the filtration of other hydraulic systems. This keeps the ongoing operating costs of the off-line filter system low.

The service life of hydraulic and lubrication system components changes significantly depending on the cleanliness class: